Technology

Titanium Bonded®:

Titanium Bonded is not painted or plated, but an application of a unique formulation of titanium and chromium nitride to the surface of cutting blades that actually penetrates and treats the metal to create a permanent bond. The patented Titanium Bonding process provides the following benefits; corrosion resistance, adhesive resistance and the process itself makes the stainless steel 3x harder than untreated stainless providing a blade that stays sharper longer.

Titanium Non-Stick:

Our proprietary new coating bonds Titanium with a non-stick formula. Highly resistant to adhesives including tape, glue, Velcro® and natural adhesive substances such as sap. This is a durable micro ceramic coating that will not wear off – up to 100,000 cuts. It is 5X harder than Stainless Steel alone and will stay sharper longer.

Carbonitride Titanium®:

Carbonitride Titanium is one of the hardest surface treatments containing titanium. Harder than carbide. Harder than chrome. Our proprietary process creates a permanent molecular bond with the blade surface. Will not flake, blister, chip, or peel. A complex crystalline structure forms which protects the blade surface against wear, staining, and damage. Patent pending technology.

Hot-Forged:

Clauss® continues to hot-forge its tools to produce a superior product from high quality rods or strips of steel, heated in a furnace and then forged from a drop hammer into the desired shape. This is an expensive process, but it is recognized as the best method to produce quality blades.

Tempered:

Clauss heat treats its scissors, shears and tools until they are harder than some striking tools, and then tempers the steel until it is pliable as spring steel. After hours of controlled processing, the steel is at its most desirable state and ready for grinding.

Precision Ground:

Clauss uses knowledge, skills and methods developed since 1877, combined with the latest technology available; to precision grind the various surfaces of its scissors, shears and tools to exacting standards.

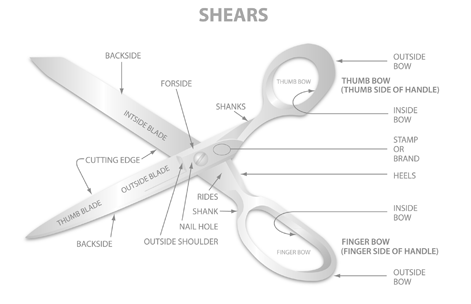

Bows:

The bows are the rings on the shears or scissors which you put your fingers through. They help you grip the tools, open and close them with one hand, and should be comfortable and form-fitting. Our bows are especially designed for each style of tool to make them best-suited to your needs as well as the task at hand.

Blades:

The art of assembling two blades and making them cut their full length properly is one of the most difficult to master, and it is this art that immediately distinguishes Clauss tools over others. Our tools provide a long, smooth uniform cut yet effortless, all the way to the tips.

Backbone:

Backbone refers to the thickness of the blade. The Clauss Backbone is the strength behind the cut. A thick backbone provides an unparalleled rigidity so the blades will not separate while cutting multiple layers of material.

Fulcrum:

Clauss ensures its scissors, shears and snips adhere to the “Transfer of Power™.” The fulcrum is an important part of this promise. Simply said, the fulcrum on all Clauss tools is an oversized fastening system that ensures the blades will not come apart while cutting.

Run:

The "run" is the "feel" you get when you cut with a pair of scissors or shears. A "good run" gives you an even, clean cut for the full length of the blade without hesitation or roughness. Clauss fine tunes the run of each of its shears to give you the best performance and feel available.

Certified Double-Plated:

Clauss has always double-plated its hot-forged tools using nickel for luster and chrome for durability, ensuring you a product that is rust and stain resistant. Other companies often only nickel plate their blades. Then they must remove the nickel plating from the inside of the blades because it peels. In that case, you have pretty blades on the outside, with bare steel, which rusts and stains, on the inside. Our process costs us more, but ensures you a product with maximum service life. The Clauss certified, double-plated process is your guarantee that these tools are the very best available.

High Carbon Cutlery Grade Steel:

Quality tools start with quality steel. The more carbon in the steel, the longer the life of the tool. Cutlery grade steel usually means high uniformity and strict control over trace elements in the steel. Clauss uses high carbon cutlery steel to ensure the best quality tools possible.

Thru-Hardened:

All Clauss hot-forged scissors and shears are thru-hardened, rather than case-hardened, which only hardens the surface. Having thru-hardened scissors and shears means that after re-sharpening, you still have a hard steel blade, and scissors and shears that will hold their edge. And if they do become dull, they can be re-sharpened over and over again.

Heat-Inducted Blades:

Heat induction is a triple-heat process. The base steel is heated, then the steel supporting the blade edges and a final heat treatment on the blade edges providing up to a 62Rc. This triple-heat process is a precise heating technology to a specific area of the blades providing a stronger, longer lasting cutting edge.

Molybdenum Steel:

Clauss also makes shears with high grade molybdenum alloy steel for those who need tools for extra heavy cutting. When hardened, molybdenum steel forms a very durable, tough, and uniform grain structure. This gives our "Moly" shears' blades excellent holding characteristics, which prolongs useful life even when used for heavy duty cutting.

Vanadium Steel:

Chrome Vanadium is used to make many different types of tools. When heat treated it has excellent properties such as strength, toughness and resistance to wear and fatigue.

Knife Edge:

"Knife edge" shears have a more acute angle on the cutting edge than "regular edged" shears. They make cutting thick, dense materials such as carpets, belting, or cording easier and put less stress and fatigue on the user.

Adjustable:

Shears with a nut and bolt assembly can be adjusted to cut and run the way you prefer them for your particular needs.

SureSet®:

A premium adjustable fastener that provides a locking pivot. It reduces friction when opening and closing and allows tension adjustment with only one hand.

Heavy Duty:

Wider, thicker blades help prevent spreading at the tips and give full cutting action even when cutting thick, dense materials. These shears have an adjustable bolt and nut assembly. Large comfortable handles and good balance help reduce blisters, calluses and hand fatigue.

High Leverage / Clauss Backbone:

Extra cutting power is developed by changing the normal power ratio of the tool. Other manufacturers do this by giving you longer handles or shorter cutting blades. Clauss provides the ultimate in high-leverage cutting by increasing the back-bone width of the blade so you get high performance and still retain the full length of cut you need.

Serration:

Some material and round objects (such as polyesters and sheet metal or rope, hose, wire and Kevlar®) tend to slip ahead of the cutting blades and need to be held by serrated edges while being cut. The types of serration Clauss uses on its tools have proven to be the best during many years of on the job testing. Clauss “Grip N Cut” serration proves for a perfect cut every time. Kevlar® is a registered trademark of the E.I. DuPont Company.

Transfer of Power™:

Transfer of Power is a technology that only Clauss offers. In testing, Clauss examined how the bows, fulcrum and blades can flex during cutting. In order to eliminate this from happening, Clauss instituted ridged bows, oversized fulcrum and industrial strong blade backbone eliminating nearly all of the flex in a scissor, shear or snip therefore transferring all of the power to the cutting edges.

Glass Filled Nylon:

Glass filled nylon bows and handles are found on many of the Clauss tools. Clauss adds glass-filled materials to polypropylene, ABS and other substraints in order to provide the strongest, most ridged handles and bows available.

Spring-Assisted:

Spring-Assisted scissor and shears allow user to reduce a portion of the cutting motion since the handles spring open. To cut, the user only needs to squeeze the handles therefore reducing fatigue from having to open and close the scissors manually.

NSF®:

NSF International, the public health and safety company™, a not-for-profit, non-governmental organization, is the world leader in standards development, product certification, education, and risk-management for public health and safety. For 60 years, NSF has been committed to public health, safety, and protection of the environment. While focusing on food, water, indoor air, and the environment, NSF develops national standards, provides learning opportunities through its Center for Public Health Education, and provides third-party conformity assessment services. NSF® is a registered trademark of NSF International.

Bamboo:

Bamboo is an environmentally sustainable organic material that regenerates itself faster than any wood. This means Camillus is preserving the environment by using a material that regenerates quickly. Bamboo handles are also moisture and stain resistant while providing a fantastic gripping surface.

Anatomy of a Shear